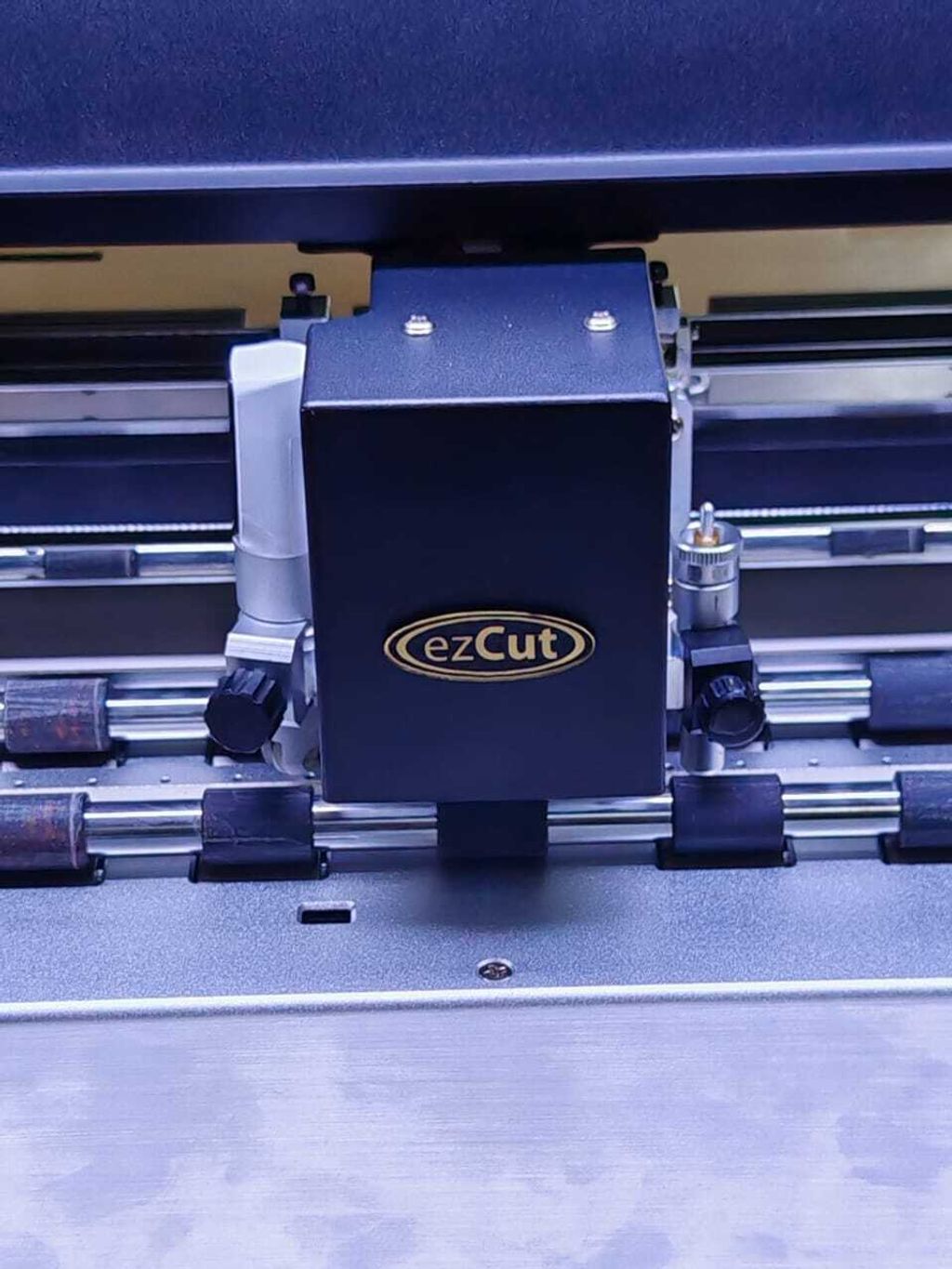

EzCut HD330 Max V3 Auto Feeder with Roller Creasing Tool

- Regular price

- RM 13,800.00

- Sale price

- RM 13,800.00

- Regular price

-

RM 0.00

Share

EzCut HD330 Max V3 Auto Feeder with Roller Creasing Tool

“Double the precision. Twice the efficiency.”

Why Choose This Machine?

When precision matters and uptime counts, this machine is engineered to deliver. With its dual-head design and smooth roller creasing tool, your production runs faster, cleaner and more reliably. Whether you’re scaling up folding-carton operations or upgrading label finishing, this machine offers the performance, durability and flexibility you require.

Video:

Applications

Ideal for:

Folding-carton creasing and cutting

Label finishing & creasing lines

Corrugated-board packaging creases

Specialty substrates for boxes, sleeves, display packaging

Small to medium-volume runs requiring high quality and repeatability

Product Overview

Boost your productivity with a high-precision dual-head auto-feeder equipped with a roller creasing tool. Built for efficiency and consistency, this machine works across a variety of substrate types, delivering sharp creases and dependable output for your packaging production needs.

Key Features & Benefits

Dual-Head Design: Two heads working in tandem for faster throughput and complex operations in one pass.

Roller Creasing Tool: Ensures smooth, consistent creases without substrate deformation.

High Precision: Built to meet demanding production standards for uniform results.

Wide Material Compatibility: Suitable for paperboard, corrugated sheets, label stock and other substrates.

Efficient Production: Dual heads + creasing roller = higher speed and less waste.

Industrial Build: Designed for heavy usage with minimal downtime.

Production Info & Warranty

Model: EzCut HD330 Max V3 Auto Feeder with Roller Creasing Tool

Includes: Machine body, dual heads, control panel, safety guard, power cable, user manual, installation & training.

Warranty: 12 months from installation (under proper maintenance).

Support: Remote technical support, spare-parts supply, optional on-site training/maintenance.

Specifications

| Item | Specification |

|---|---|

| Max. media width | 370 mm |

| Max. cutting width | 340 mm |

| Auto contour cut | Camera (automatic contour cutting) |

| Control panel | 4.3″ touch screen |

| Motor | High-speed servo motor |

| Positioning mode | QR code / Dot / Right-angle |

| Number of heads | 2 |

| Blade type | Roland blade |

| Machine size | L 768 mm × W 455 mm × H 336 mm |

| Packing size | L 890 mm × W 580 mm × H 570 mm |

| Gross/Net weight | 63 kg / 46 kg |

| Cutting accuracy | ±0.01 mm |

| Repeatability | 0.082 mm |

| Max. material thickness | 600 gsm |

| Max. cutting speed | 1600 mm/s |

| Max. force | 3000 g |

| Connect/interface | USB cable / U-disk / Web cable / WiFi |

| Power | < 150 W |

| Working environment | +5 °C to +35 °C |

| Power supply | 100 V-240 V (auto-adaptive) |

| Suitable materials | Self-adhesive sticker / coated paper / PVC |

| Support software | CDR / SignMaster Pro V5 |

| Memory | 1 GB |

| Supported OS | Windows 10 / 11 |

#RotaryCreasing #DoubleHeadMachine #PackagingProduction #FoldingCarton #LabelFinishing #HighPrecision #IndustrialCreasing #PackagingSolutions #PackagingMachinery #EfficiencyBoost